The company is a one-stop integrated product manufactur […]

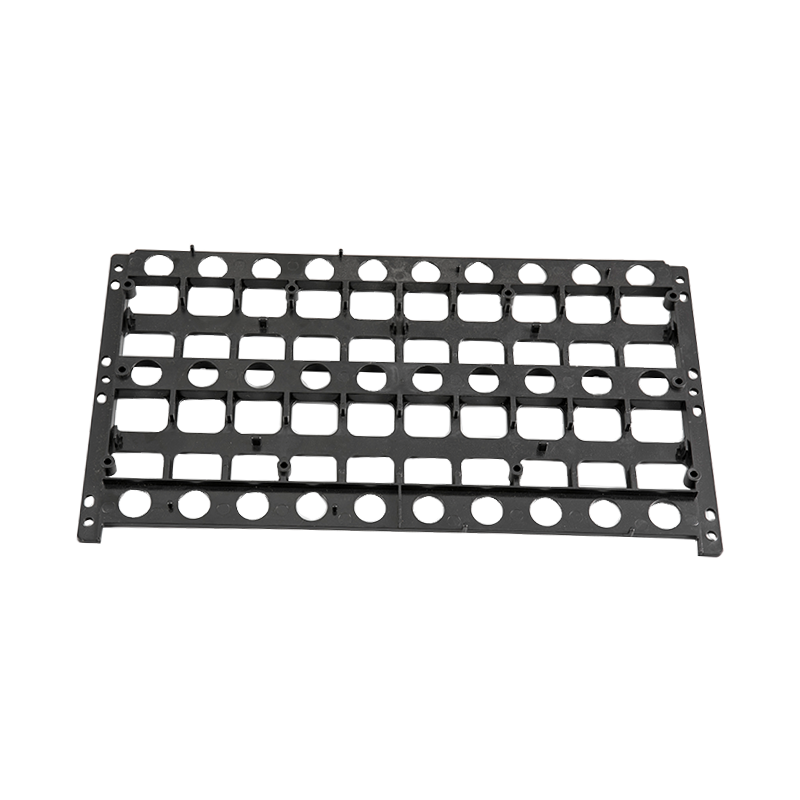

The company is a one-stop integrated product manufacturer of precision molds and injection molding in the industry. The company takes precision mold development, high-complex injection molding process and automated assembly technology as its core, and is committed to "electronic integration, precision, and lightweight "The direction of development. The company has been deeply involved in the field of precision molds and injection molding for many years. It has strong product design, mold development capabilities and highly complex injection molding technology. At the same time, it has a large number of advanced imported processing equipment. The company is in a higher level of competition in the industry. in.

At the same time, with the future development of electrification, intelligence, networking, and sharing of automobiles, the company will strive for more high-end precision products with high added value and electronic integration in the future, gradually increase the proportion of automotive electronics products, and improve market competitiveness . In the future, the company will focus on emerging areas such as new energy, intelligent driving, and Internet of Vehicles, and will actively seek internal and external development opportunities in conjunction with the future development trend of the automotive industry.

General requirements for mold design:

1. Reasonable mold design is mainly reflected in the quality of plastic products (appearance quality and dimensional stability);

2. It is convenient, fast, concise, saves money and manpower when processing and manufacturing, leaving room for correction and improvement;

3. It is safe, reliable and easy to maintain during use;

4. In injection molding, there is a shorter molding cycle and a more commonly used life, as well as a reasonable mold manufacturing process.

Mold design should be based on the following aspects:

1. According to the drawings and samples provided by the customer and similar structures in the past, analyze the mold structure and optimize the mold structure.

2. The accuracy of the dimensions and the correctness of the relevant dimensions, except for the assembly dimensions, the other dimensions must be strictly controlled within the allowable tolerance range.