High speed injection molding is a great new technique t […]

High speed injection molding is a great new technique that allows the design and production of parts quickly, easily, and accurately. By using this method of mold making, companies have the ability to cut down the time required for a part to be created. It also reduces costs, as they do not have to purchase material and labor for each individual part. With the many benefits of this method, it is clear that high-speed injection molding is a wonderful method for many industries.

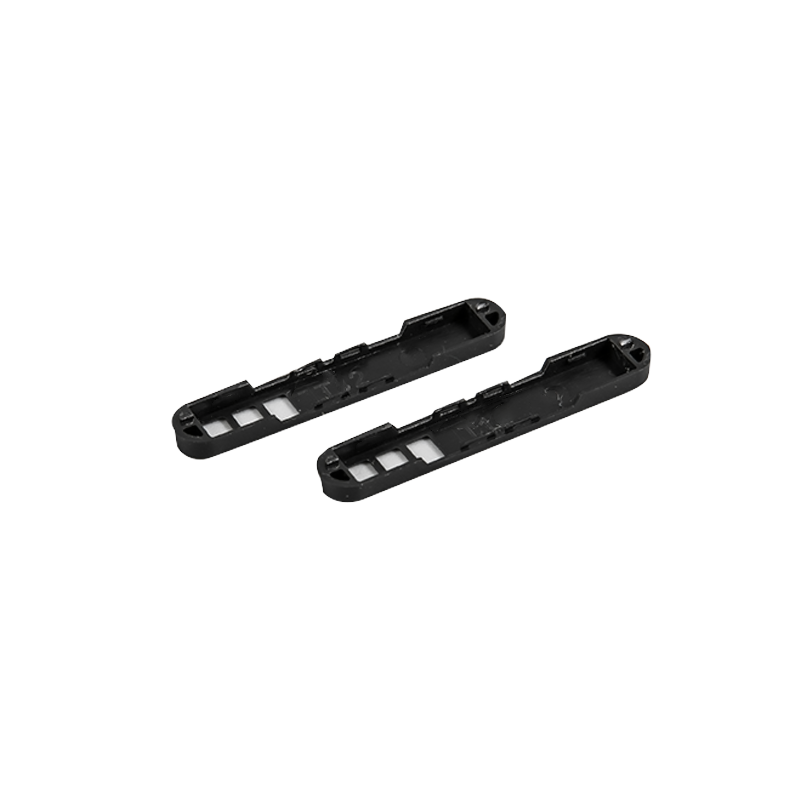

A high speed injection molding process allows the molder to create an item that can be quickly molded. These items are typically used in the electronics industry, but they are also being used in other fields. It can create an item that can be quickly and easily produced. Items made with this type of process can also be used to create parts that are very intricate in nature, which requires intricate design. This can allow the design to be changed at any time and to ensure that each part is completely different than the last one. This also allows a company to test each product before using it in any manufacturing setting. There are many companies that use high-speed injection molding to create these intricate items.

Because of the high speed injection molding process, it is possible to create products that are extremely unique. These unique products allow companies to create things that other companies cannot create. These products allow a company to create products that cannot be created using other methods. This type of process allows companies to create products that are extremely unique, which helps them to create more products in a shorter amount of time. It can help a company to have an endless amount of options when it comes to creating unique products. The products can be created quickly, efficiently, and accurately. This is the main reason that many companies use this process, as it allows them to reduce the time needed for each part to be created.